Bottle Process

|

GM-1 Split System

GM-2 System

H-200 System

H-100VT

H-100V

|

Windshield / Plate

|

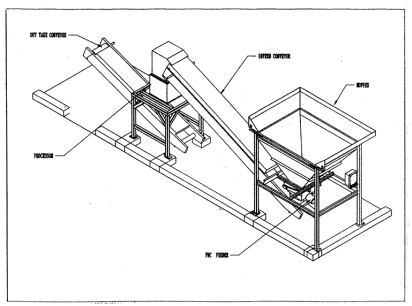

The GLS System

Crushes Windshields into manageable pieces.

Separates the PVB laminate from the glass. Turns the windshields into usable aggregate |

Full Bottle Process

Mobile Process

Several Of Our Systems Can Be Converted Into Portable Units! This Has Become A Great Way For Counties And Smaller Businesses To Share The Use And Cost Of One Machine!

|

Mobile Unit - Example #1

Mobile Unit - Example #2

|

Custom Solutions

Glass Aggregate Systems designs, builds, and supports a complete line of glass recycling processors, and because we do this from our state-of-the-art manufacturing facility, we can provide the necessary services required to customize as needed.

We develop relationships with our customers by listening to their unique challenges and working with them to find the best, most cost-effective way to solve their glass recycling problem. Should our standard line of equipment not accomplish what the customer needs, we can draw upon our resources to fit the customers’ specifications.

Replacement parts are readily available from our factory. When customizing, we still try to incorporate standard components, making service parts also readily available.

All systems, whether standard or unique, are set-up and tested at our factory prior to shipping. Our customers are always welcome and encouraged to attend giving them the opportunity to see first-hand how the process works and view the finished product.

Our equipment is American made – manufactured in the USA in Faribault, Minnesota and customized for installations world–wide.

We develop relationships with our customers by listening to their unique challenges and working with them to find the best, most cost-effective way to solve their glass recycling problem. Should our standard line of equipment not accomplish what the customer needs, we can draw upon our resources to fit the customers’ specifications.

Replacement parts are readily available from our factory. When customizing, we still try to incorporate standard components, making service parts also readily available.

All systems, whether standard or unique, are set-up and tested at our factory prior to shipping. Our customers are always welcome and encouraged to attend giving them the opportunity to see first-hand how the process works and view the finished product.

Our equipment is American made – manufactured in the USA in Faribault, Minnesota and customized for installations world–wide.